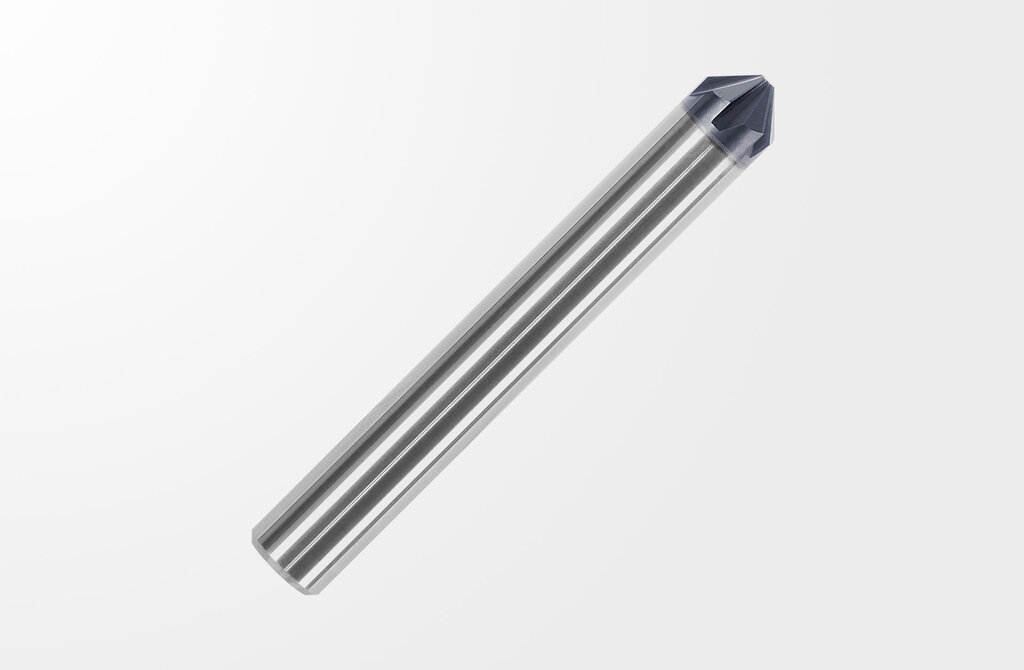

Solid Carbide End Mills

UNIVERSAL CUTTING TOOLS FOR A BROAD RANGE OF APPLICATIONS

Discover now

Filter

Filter

View

sort by

25 Products

25 Products

Displayed items